- Key Takeaways

- Understanding DIN Rail Power Supplies

- How DIN Rail Power Supplies Operate

- Key Features of DIN Rail Power Supplies

- Types of DIN Rail Power Supplies

- Benefits of Using DIN Rail Power Supplies

- Selecting the Right DIN Rail Power Supply

- Applications of DIN Rail Power Supplies

- Installation and Maintenance Tips

- Innovations in DIN Rail Power Supply Design

- Summary

- Frequently Asked Questions

A DIN rail power supply is an electrical device that converts mains AC voltage into a stable DC output. It’s designed for easy mounting on DIN rails, making it ideal for industrial control panels. In this article, you’ll learn about what is a DIN rail power supply, its operation, types, key features, and benefits.

Key Takeaways

- DIN rail power supplies efficiently convert AC voltage to stable DC output, ensuring reliable operation in industrial applications.

- Their compact design, built-in protections, and modularity enhance installation ease and system reliability, making them ideal for space-constrained environments.

- Choosing the appropriate DIN rail power supply involves considering output voltage requirements, environmental conditions, and safety certifications for optimal performance.

Understanding DIN Rail Power Supplies

DIN rail power supplies are specialised electrical devices that provide reliable and efficient power in industrial applications. They convert mains AC voltage into a stable DC output, allowing connected devices to operate smoothly. This conversion is achieved through the use of rectifying diodes and electronic regulation, which together maintain a consistent and regulated DC output voltage.

One of the standout features of DIN rail power supplies is their design for easy installation on standard DIN rails. These rails allow for compatibility with various control panel configurations, making DIN rail power supplies a flexible and adaptable choice for many industrial setups. Their compact design efficiently utilises space within control panels, a significant advantage in environments where space is limited.

The benefits of DIN rail power supplies extend beyond just their functional capabilities. Their ease of installation, space efficiency, and reliability make them a preferred choice over traditional power supplies in many industrial settings. These power supplies are integral components in modern industrial systems due to their efficiency and reliability.

How DIN Rail Power Supplies Operate

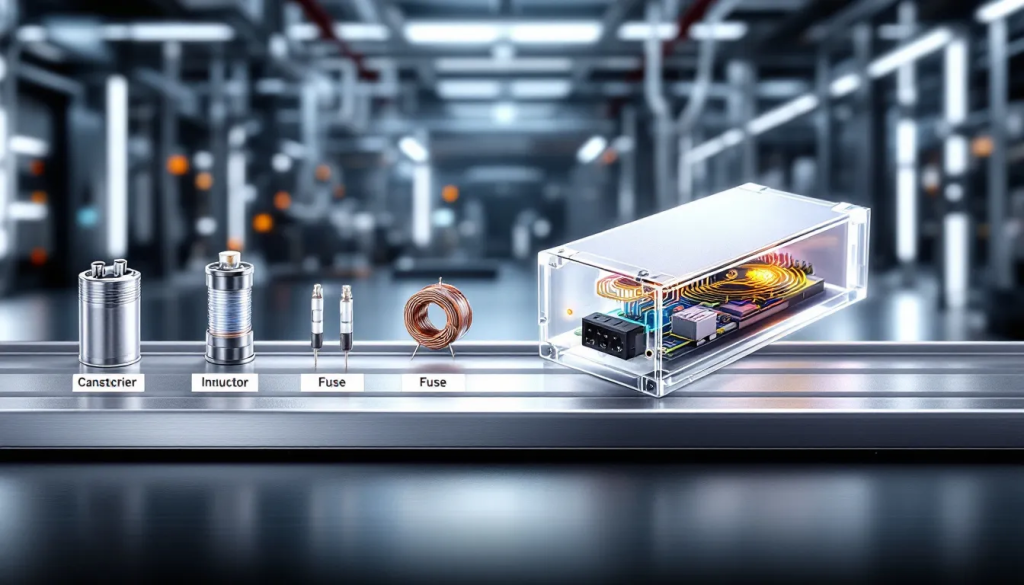

DIN rail power supplies convert AC power into regulated DC voltage, starting with rectification. Rectifying diodes allow current to flow in one direction, converting AC voltage to DC. This is followed by a voltage regulation stage, where feedback control and electronic components ensure a stable output voltage.

Many DIN rail power supplies include filtering stages that reduce ripple and noise to further enhance the quality of the DC output. This is particularly important in sensitive industrial applications, where even minor fluctuations in power can lead to significant disruptions. Many modern units utilise switching technology, improving efficiency and reducing heat generation during operation.

The combination of these technologies ensures that DIN rail power supplies can deliver reliable, high-quality power to various industrial systems. Their ability to maintain a regulated DC output voltage and reduce noise and heat makes them superior to most traditional power supplies. These key features make them the backbone of many industrial and automation systems.

Key Features of DIN Rail Power Supplies

DIN rail power supplies come equipped with a range of features designed to enhance their performance and reliability. Built-in protections, such as short-circuit and overvoltage safeguards, ensure the safety and longevity of connected electrical components by preventing damage from power surges or faults.

Their compact design allows for easy installation in tight spaces, which is particularly beneficial in crowded industrial control panels. DIN rail power supplies’ compact size ensures they can fit seamlessly into these setups without compromising on performance.

Recent design advancements have improved energy conversion rates, making DIN rail power supplies more efficient in delivering electrical power and enhancing energy efficiency. These improvements reduce energy losses and lower operational costs, essential in industrial environments.

These features make DIN rail power supplies a robust and reliable power solution for modern industrial systems.

Types of DIN Rail Power Supplies

DIN rail power supplies come in various types, each designed to meet specific power requirements. Single-phase DIN rail power supplies are used for low-power applications, offering a simple and cost-effective solution for many industrial needs. They are ideal for powering control panels and small machinery with relatively low power demands.

Three-phase DIN rail power supplies handle the increased power demands of larger industrial machinery and equipment, making them suitable for intensive applications. Distributing power across three phases ensures a balanced load and improved efficiency.

DC-DC converters are designed to convert one DC voltage to another, ensuring that all system components receive the appropriate power by providing the necessary voltage conversion.

Redundant DIN rail power supplies ensure continuous power in critical applications by providing a backup power source that automatically switches if the primary supply fails. This feature is crucial in environments where uninterrupted power is essential, such as data centres and critical industrial processes.

Benefits of Using DIN Rail Power Supplies

A primary benefit of DIN rail power supplies is their modularity and ease of replacement. In industrial systems, components often need to be replaced or upgraded, and the modular design of DIN rail power supplies simplifies this process. Modularity also allows for easy customisation of power distribution systems to meet specific needs.

Their robust durability ensures consistent performance even in challenging industrial settings. Designed to withstand harsh conditions, including extreme temperatures, humidity, and dust, they require less maintenance and have a longer lifespan, making them a cost-effective choice for many applications.

These power supplies enhance efficiency, reliability, and system organisation through versatile additional power supply features and safety mechanisms. Incorporating built-in protections and advanced design elements, they help ensure smooth operation, reducing downtime and improving productivity. Our power supply solutions are designed to meet these needs effectively.

Selecting the Right DIN Rail Power Supply

Choosing the right DIN rail power supply involves several key considerations. First, determine the required DC output voltage, which is commonly 12V, 24V, or 48V. A suitable power supply aligns with the specifications and load requirements, which is crucial to prevent instability and ensure reliable operation.

Another important factor is the operating environment. Many DIN rail power supplies are optimised to operate efficiently within a temperature range of -30°C to +70°C. To ensure optimal performance, select a power supply that can withstand specific environmental conditions, such as humidity and dust exposure.

Safety certifications and protections are also critical. Ensure compliance with standards like UL 508 for industrial control applications in North America. Look for power supplies with built-in protections such as overvoltage, overcurrent, and short-circuit protection for safe and reliable operation.

Applications of DIN Rail Power Supplies

DIN rail power supplies are widely used in various industrial and automation applications. In factory settings, they support machinery and control operations, providing the necessary power for smooth system operation. Control panels in industrial applications rely on these power supplies to ensure all connected devices receive stable and reliable power.

These power supplies, which provide DC voltage to devices such as sensors and actuators, greatly benefit automation systems. They are essential for ensuring industrial automation processes operate efficiently and without interruption. In telecommunications equipment, stable power delivery is critical for maintaining communication networks, making these power supplies indispensable.

Their versatility makes them suitable for a wide range of applications, from industrial control equipment to telecommunications. The ability to provide reliable power in various settings underscores their importance in modern industrial systems.

Installation and Maintenance Tips

Proper installation and maintenance ensure the reliable operation of DIN rail power supplies. To ensure a proper fit, the installation space must be compatible with the device’s dimensions. Appropriate tools, such as wire strippers and screwdrivers, also ensure a successful installation. Grounding the power supply and DIN rail prevents electrical hazards during operation.

Thermal management is also critical. Ensure adequate airflow around the unit to prevent overheating, as DIN rail power supplies are designed to effectively dissipate heat. Minimising cable length and diameter helps reduce energy loss and heat generation, especially for higher loads.

Maintenance includes verifying connections for tightness and correct polarity before powering on the system. Choosing a power supply with built-in protections, such as short-circuit and overload protection, ensures safe operation in demanding environments. DIN rail power supplies’ modular design enables straightforward maintenance and upgrades without disrupting the entire system.

Innovations in DIN Rail Power Supply Design

Recent advancements in DIN rail power supply design highlight notable improvements in adaptability and user-friendliness. These power supplies now offer a universal input voltage range, making them versatile for numerous industrial applications. The introduction of innovative DIN rail clips simplifies the installation process, allowing for tool-free mounting and removal.

These power supplies deliver high-output power through convection cooling, eliminating the need for extra cooling components, thereby enhancing efficiency and reducing system complexity. They can manage a 150% overload for brief periods, accommodating high startup loads in industrial environments.

With a lifespan exceeding 80,000 hours due to enhanced design and materials, these power supplies ensure long-term reliability. Maintenance-free and tool-free push-in terminals further improve ease of installation and upkeep. These innovations ensure that DIN rail power supplies continue to meet the changing needs of industrial and automation systems.

Summary

In summary, DIN rail power supplies are indispensable components in modern industrial applications. Their ability to convert mains AC voltage into stable DC output, coupled with features like built-in protections and compact design, makes them a reliable and efficient power solution. The various types, including single-phase, three-phase, DC-DC converters, and redundant models, cater to diverse power requirements, ensuring versatility across different applications.

The benefits of using DIN rail power supplies, such as modularity, durability, and enhanced efficiency, make them a preferred choice in many industrial settings. With proper selection, installation, and maintenance, these power supplies can provide long-term reliability and support the smooth operation of industrial systems. As innovations continue to evolve, DIN rail power supplies will remain at the forefront of industrial power solutions.