Why We Need Power Factor Correction (PFC)

Power Factor Correction (PFC) is essential in power supply units (PSUs) and electronic device design. Particularly for devices with significant power draw or those subject to stringent regulatory standards. PFC is highly recommended for devices intended for markets with strict regulations, such as the European Union, which enforces specific power factor levels and harmonic emission limits to maintain grid stability and efficiency.

Poor power factor can cause increased heating losses, potential power failures, and strain on the power grid, making PFC crucial in applications involving inductive or capacitive loads that cause displacement, or nonlinear loads like rectifiers that cause distortion. By implementing PFC, devices minimise their impact on the power grid, reduce energy waste, and meet regulatory requirements.

With global energy demands growing and regulatory standards becoming more stringent, integrating PFC into power supplies is essential for both environmental sustainability and operational efficiency. This integration ensures devices operate efficiently, comply with regulations, and contribute to a more stable and efficient power grid.

What is Power Factor?

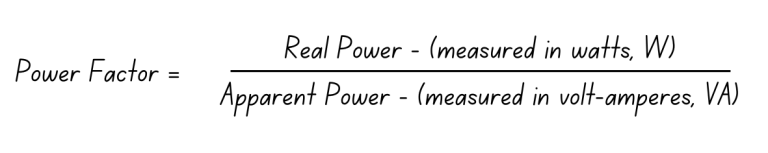

To understand PFC, it’s essential first to grasp the concept of power factor, which is a measure of how effectively electrical power is being used.

The power factor of an AC power system is defined as the ratio of the real power absorbed by the load to the apparent power flowing in the circuit and is defined by the formula:

Due to energy stored in the load and returned to the source, the apparent power can exceed the real power, causing more current to flow in the circuit than necessary for transferring just the real power. A power factor of less than one indicates that voltage and current are out of phase. A negative power factor happens when the device, typically the load, generates real power that flows back to the source.

In an electric power system, a load with a low power factor draws more current than one with a high power factor for the same amount of useful power. This increased current leads to higher energy losses in the distribution system and necessitates larger wires and other equipment.

The Difference Between Efficiency and Power Factor

In our daily lives, we use Alternating Current (AC) for household appliances, which can be categorised into:

Resistive loads – which include any appliance that has a heating element such as toasters and coffee makers.

Inductive loads – any appliance that has moving parts such as washing machines and fans.

When AC powers inductive loads, the current waveform lags the voltage waveform, leading to inefficient power use. However, if the current and voltage waveforms are in phase, the power factor approaches 1, indicating efficient power transfer with minimal energy loss.

Efficiency measures how well household electronics use power, directly affecting electricity bills and heat generation. A low-efficiency power supply generates more heat, necessitating better cooling to meet environmental requirements.

Power factor, on the other hand, reflects the ratio of power usage to waste. While it has a lesser impact on electricity bills, a low power factor can lead to significant energy losses, especially as the demand for power increases with the improvement of electronic devices.

For more information on this, we found a detailed and useful video by Prof MAD, fully explaining how Power Factor works!

Types of Power Factor Correction

PFC can be divided into two main categories: Passive PFC and Active PFC.

Passive PFC

Passive PFC uses passive components like inductors and capacitors to improve the power factor. The PF value of passive PFC power supplies typically ranges between 70% and 80%. Passive PFC designs are simple, cost-effective, and involve a low pass filter to reduce high harmonic distortion, leaving only the 50Hz or 60Hz fundamental frequency.

However, passive PFC has its drawbacks:

- Larger and heavier components

- Lower efficiency due to thermal and voltage drops

- Manual voltage switching for different input voltages

Active PFC

Active PFC is preferred for its superior efficiency and performance. It uses a switching regulator operating at a high switching frequency, achieving a theoretical power factor of over 95%. The advantages of active PFC include:

- Enhanced Efficiency: Power distribution operates at its maximum efficiency, reducing energy wastage.

- Reduced Harmonics: Active PFC significantly diminishes total harmonic distortion.

- Voltage Correction: Automatically corrects for AC input voltage, accommodating a full range of input voltages from 87V to 266V at 47Hz to 63Hz.

Active PFC circuits are designed as boost regulators, ensuring the voltage across the load is greater than the peak input voltage. This design allows active PFC to maintain a constant intermediate voltage to drive the DC/DC converter, simplifying its requirements and complexity. Due to smaller inductive components, active PFC power supplies are lighter and more compact.

However, active PFC comes with higher complexity and cost due to the need for additional components like PFC control ICs, high-voltage MOSFETs, and other circuitry. Despite these drawbacks, the benefits of active PFC make it the ideal choice for power supplies.

The Importance of PFC Standards

Environmental protection is a significant concern. Power Factor Correction plays a critical role in the design of modern electrical devices due to its impact on power efficiency and regulatory compliance.

An example of these standards is:

IEC 61000-3-2: An international standard by the IEC, it specifies limits for harmonic emissions from equipment connected to public low-voltage systems, categorising devices and setting specific emission and power factor limits.

EN 61000-3-2: The European version of IEC 61000-3-2, required for products in the EU, ensures compliance with EMC regulations by limiting harmonic currents drawn from the public supply system.

Energy Star: In the US, this voluntary program sets power factor correction guidelines, requiring a minimum power factor of 0.9 for equipment at maximum rated output.

IEEE 519-1992: This IEEE standard offers guidelines and limits for harmonic content and power factor for devices and systems connected to power networks.

GB/T 14549-93: A Chinese standard setting requirements for harmonic emissions and power factor in grid-connected equipment.

These standards ensure that devices do not negatively affect the power grid. By improving power factor, devices operate more efficiently, reduce energy waste, and comply with regulations, making them viable for sale in strict markets.

Contact Us Today

Ready to enhance your power supply efficiency and performance?

Contact us today to discuss how our advanced Power Factor Correction solutions can meet your needs. Our expert team is here to provide tailored advice and solutions for all your power supply requirements. Let us help you achieve optimal efficiency and reliability in your power systems. Reach out now to start the conversation!